FEATURES

Using all-steel welding structure, vibration to eliminate stress, com-plete machine floor boring and milling processing, vertical precision is good, machine floor boring, machine strength, good rigidity;

Hydraulic transmission, smooth and reliable;

The CNC system adopts the Dutch CybTouch 8 system, which is the special control system of the two-axis control of the twisting axis synchronous bending machine, the control of the X-axis and Y-axis servo motor, the precise positioning control of the mechanical stopper and the backstop of the cylinder Shaft rear block automati-cally lift

System uses 7" large LCD display, Chinese menu, user-friendly interface, intuitive, easy to operate;

Processing procedures using file management, large capacity can save 100 procedures, each program 25 steps;

With semi-automatic, manual function, high precision, equivalent control accuracy of up to 0.08mm;

Single, two-way positioning, automatic concessions, parameter memory, with high reliability, compatibility and other characteris-tics;

Rear block with ball screw, linear guide, fast, effectively improve the processing accuracy, speed.

Safe photoelectric protection system, the effective protection of the safety of workers.

Optional CNC

|

ESTUN E21

|

|

ESTUN E200P

|

|

ESTUN E300

|

|

DELEM DA415

|

Higher Quality Mould

Whole hardened high precision CNC press brake tooling,it is durable.

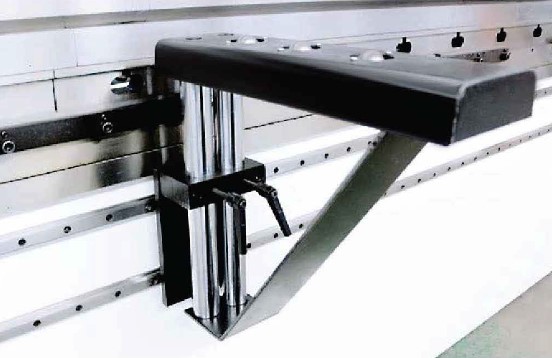

Mobile Font Support

Moveable front support system, to help you to bend, make a comfort-able and efficient working.

Premium Backgauge

Equipped with high efficient servo motor, ball screw, linear guide rail, high precision operation, fast speed.

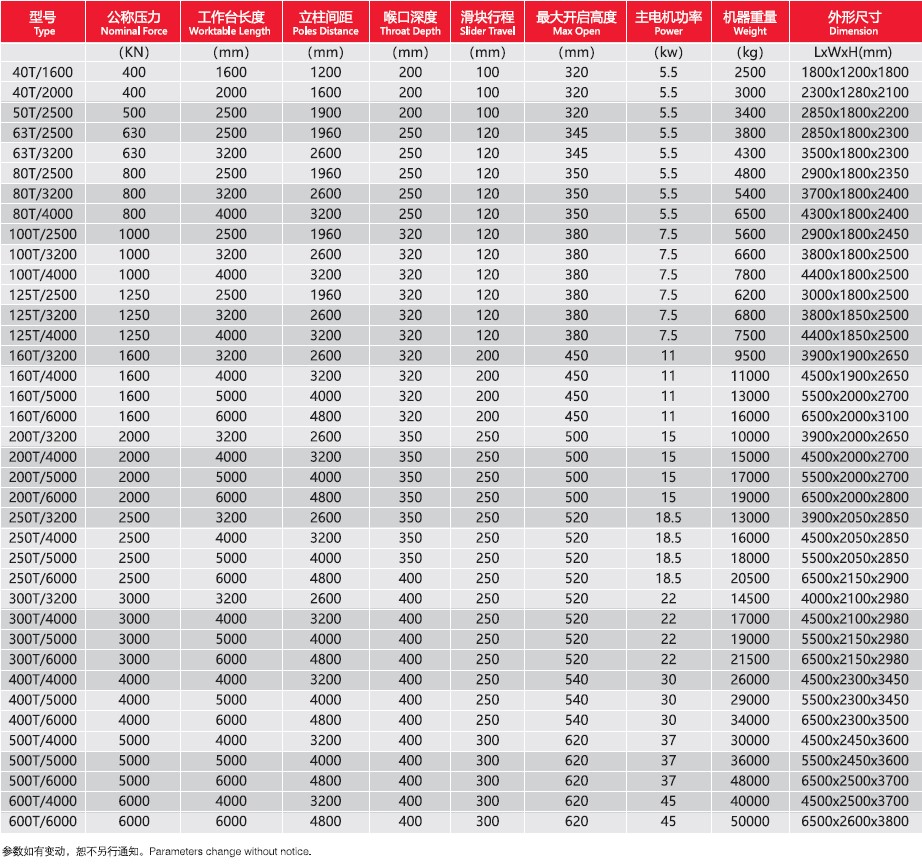

Technical Parameters

![]() 650 A, Quốc lộ 1A, khu phố 9, Phường Bình Hưng Hòa B, Quận Bình Tân, TP. Hồ Chí Minh

650 A, Quốc lộ 1A, khu phố 9, Phường Bình Hưng Hòa B, Quận Bình Tân, TP. Hồ Chí Minh

![]() 0328 696 898

0328 696 898

![]() tranhoangthy0307@gmail.com

tranhoangthy0307@gmail.com

![]() www.chengxingvietnam.com

www.chengxingvietnam.com

Hotline

Hotline