Features

The host adopts the QC12Y series model, with the economical special numerical control system;

The post - block position is displayed in real time;

Multi-step programming function, after the automatic operation and continuous positioning of the material, the automatic accurate adjust-

ment of the post - block position;

The shearing count function shows the shear number in real time;

The rear block adopts the inlet ball screw to ensure the positioning accuracy of the rear retaining material, and the machining precision is higher.

OPTIONAL CNC

|

ESTUN E21S

|

|

ESTUN E200PS

|

|

DELEM DAC310

|

|

DELEM DAC360

|

Front working table

Using rolling steel ball, reduces friction, ensure the workpiece surface is not scratched.

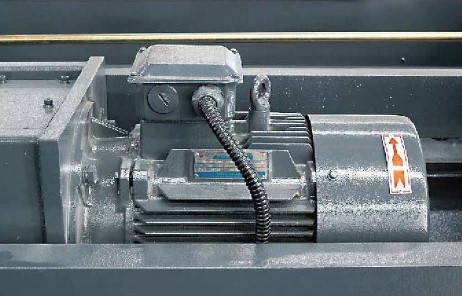

BRAND MOTOR

Use brand motors, not only low noise, but also long service life.

Fast blade gap adjustment

Simple and quick manual adjustment, the implementation of the blade gap adjustment.

High precision back gauge

High precision backgauge, unique synchronous transmission mechanism, stable and reliable.

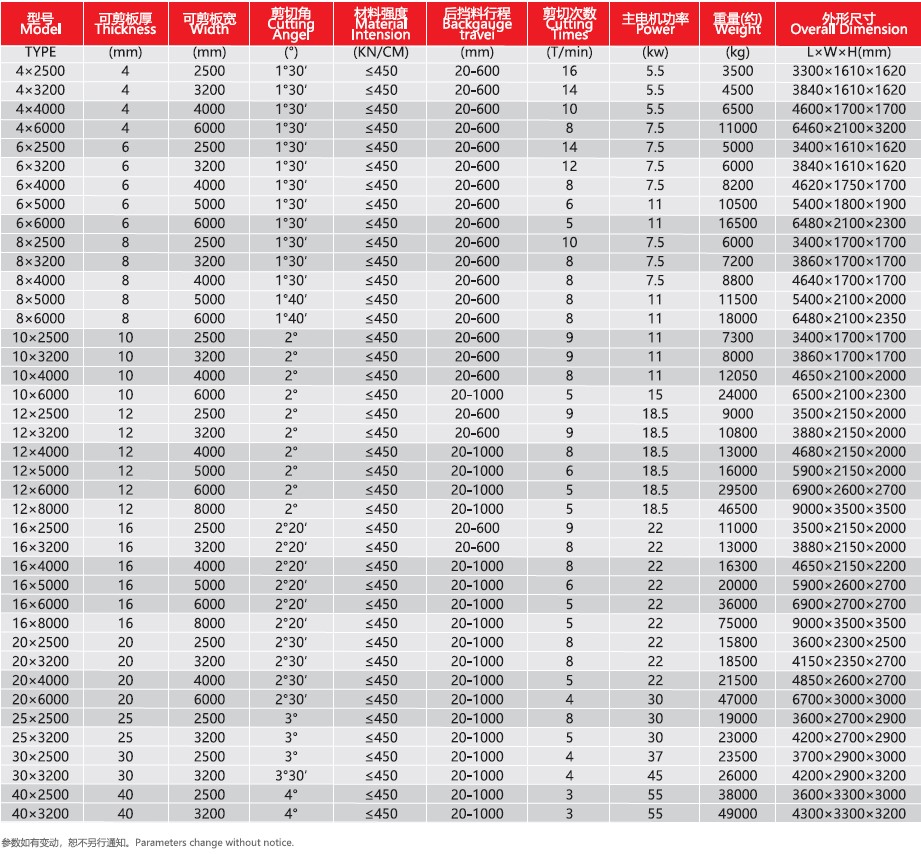

Technical Parameters

![]() 650 A, Quốc lộ 1A, khu phố 9, Phường Bình Hưng Hòa B, Quận Bình Tân, TP. Hồ Chí Minh

650 A, Quốc lộ 1A, khu phố 9, Phường Bình Hưng Hòa B, Quận Bình Tân, TP. Hồ Chí Minh

![]() 0328 696 898

0328 696 898

![]() tranhoangthy0307@gmail.com

tranhoangthy0307@gmail.com

![]() www.chengxingvietnam.com

www.chengxingvietnam.com

Hotline

Hotline