The system consumes less energy with the servo motor.

Oil distribution according to needs has no restriction loss to achieve the energy-saving indeed.

Low temperature-rise reduces the risk of oil leakage, which has better stability and can increase the working life of hydraulic press system and oil cylinder.

Gear pump reduces working noise and sensitivity of oil cleanliness, low maintenance

Precision of ram position or manufacture isn't lower than propor-tional valve control system, even higher. The ram repositioning precision is ±0.01mm, highest precision will be ±0.005mm.

The consumption of hydraulic oil reduces 70%.

The simpler installation method can improve efficiency.

Flexible installation meets populous needs.

Better economic and higher performance-to-price ratio.

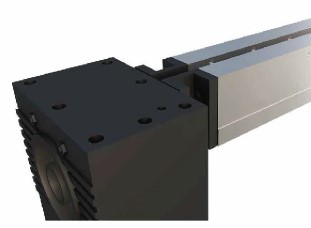

NEW HIBRID DRIVE

Fast and stable action, much faster response speed than the proportion-al valve control, 30% faster bending cycle time than the electro-hydrau-lic synchronous CNC bending machine, and its energy consumption is only about 40% - 60% of the electro-hydraulic synchronous CNC bend-ing machine. At the same time, the system has the characteristics of low noise and high efficiency.

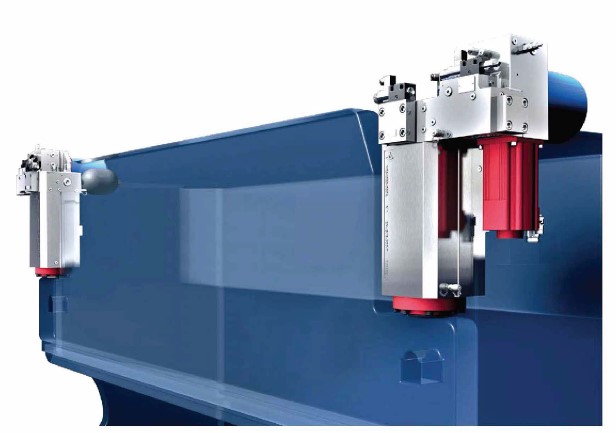

MECHANICAL DEFLECTION COMPENSASION

The deflection compensation system can perform real-time correction and is equipped with the most advanced sensors, so that the user can obtain accurate and constant bending results even if the workpiece is longer than 3 meters.

|

CybTouch8 (瑞士CT8)

|

|

CybTouch12 (瑞士CT12)

|

|

CybTouch 15 PS (瑞士CT15)

|

|

DA-52s(荷兰DELEM)

|

|

DA-53T (荷兰DELEM)

|

|

DA-58T (荷兰DELEM)

|

|

DA-66T (荷兰DELEM)

|

|

DA-69T(荷兰DELEM)

|

|

KV-S630 (意大利ESA)

|

|

KV-S640(意大利ESA)

|

![]() 650 A, Quốc lộ 1A, khu phố 9, Phường Bình Hưng Hòa B, Quận Bình Tân, TP. Hồ Chí Minh

650 A, Quốc lộ 1A, khu phố 9, Phường Bình Hưng Hòa B, Quận Bình Tân, TP. Hồ Chí Minh

![]() 0328 696 898

0328 696 898

![]() tranhoangthy0307@gmail.com

tranhoangthy0307@gmail.com

![]() www.chengxingvietnam.com

www.chengxingvietnam.com

Hotline

Hotline